Magnetic Equipments- Electro Over Band Magnetic Separator

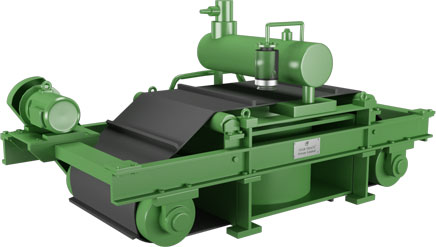

Installed above the conveyor to remove scrap iron buried in thick material layer. Equipped with a tough,vulcanized rubber belt to remove scrap irons continuously. High-quality Aluminum or Copper wire used. Optional magnetic force at the suspension height rated:500Gs,700Gs,900Gs,1200Gs,1500Gs or above, which will be determined by the requirements of the client. Optional stainless steel clad belt. Heavy-duty construction.Compact design. Electric motor with chain drive transmission. Departure of the belt can be recrified automatically. Low noise.Low maintenance. Can be suspended either crossbelt (perpendicular to the product flow) or inline (parallel above the produst flow).

Air- cooled, self cleaning electro magnets are suspended overhead magnets designed foremoving ferrous stee l and other magnetic materials from your burden during the crushing, screening and sorting processes.

An armor clad conveyor belt travels around the magnet and carries the ferrous material that is drawn upward, away and into collecting hoppers or onto the ground. These units are typically installed either in-line (As in the photo), or cross belt (90 deg. Across the conveyor belt.) They are ideal for removing miscellaneous metallic debris from crushed and recycled material and are designed to provide long-term, trouble free operation. All units are equipped with the required rectifier to power the magnet.

Features:- Magnets equipped with heavy steel side plates.

- Aluminium Wound coils with class H insulation.

- Two year warranty against magnetic coil burnout .

- Solid steel core .

- NEMA 4X terminal box.

- Four pulley design.

- Adjustable screw take ups on tail pulley.

- 5 hp motor for self-cleaning belt.

- Stainless Steel Clad Belt INCLUDED.

- Mixed demolition debris.

- Crushed or broken aggregate.

- Mixed solids at MRF facilities.

- Refuse at mixed waste facilities.

- Shredded tire processing.

- Mill and Scrap Yard Processing.

* Magnet size is based upon application evaluation. (i.e. belt width, belt speed burden depth, size of recoverable ferrous Burd)

| MODEL | DIMENSIONS | WEIGHT |

| STR-36 | 100" l x 44" w x25" | 1452 |

| STR-42 | 106" l x 50" w x25" | 2314 |

| STR-48 | 112" l x 56" w x25" | 3267 |

| STR-54 | 118" l x 62" w x25" | 4220 |

Installed above the conveyor to remove scrap iron buried in thick material layer. Equipped with a tough, vulcanized rubber belt to remove scrap irons continuously. High-quality Aluminum or Copper wire used. Optional magnetic force at the suspension height rated:500Gs,700Gs,900Gs, 1200Gs, 1500Gs or above, which will be determined by the requirements of the client. Equipped with fan-cooling system. Heavy-duty construction. Compact design. Electric motor with chain drive transmission. Departure of the belt can be rectified automatically. Low noise, Low maintenance, much power saved. Can be suspended either cross belt ( perpendicular to the product flow) or inline ( paralled above the product flow).

STRB Plate Electromagnetic Separators:Installed above the conveyor to remove scrap iron buried in thick material layer. Equipped with a tough,vulcanized rubber belt to remove scrap irons continuously. High-quality Aluminum or Copper wire used. Optional magnetic force at the suspension height rated:500Gs,700Gs,900Gs,1200Gs,1500Gs or above, which will be determined by the requirements of the client. Optional stainless steel clad belt. Heavy-duty construction.Compact design. Electric motor with chain drive transmission. Departure of the belt can be recrified automatically. Low noise.Low maintenance. Can be suspended either crossbelt (perpendicular to the product flow) or inline (parallel above the produst flow).

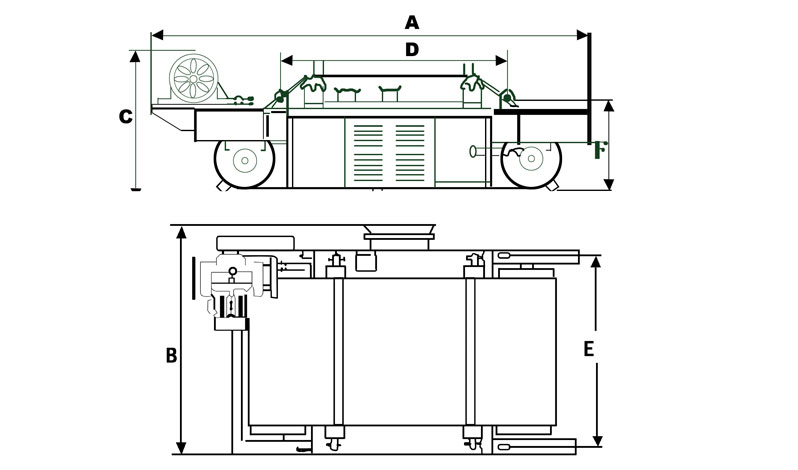

| MODEL | Belt Width mm | Colling Method | Suspension Height Rated (SHR) | Excitaion Power | Driver Power kw | Coller Power kw | Outline Dimension mm | Weight kg | |||||

| A | B | C | D | E | F | ||||||||

| STRA-6 | 650 | Fan Cooling | 200 | <3 | 1.5 | 0.37 | 2240 | 1273 | 733 | 881 | 873 | 436 | 1030 |

| STRA-8 | 800 | 250 | <4.5 | 2.2 | 0.55 | 2465 | 1539 | 735 | 1240 | 1073 | 537 | 1830 | |

| STRA-10 | 1000 | 300 | <6 | 3.0 | 0.55 | 2650 | 1727 | 821 | 1365 | 1273 | 650 | 2760 | |

| STRA-12 | 1200 | 350 | <9.5 | 4.0 | 1.1 | 3090 | 2052 | 908 | 1660 | 1523 | 761 | 3355 | |

| STRA-14 | 1400 | 400 | <12 | 4.0 | 1.5 | 3266 | 2243 | 974 | 1930 | 1723 | 841 | 4535 | |

| STRA-16 | 1600 | 450 | <14.5 | 5.5 | 2.2 | 3564 | 2505 | 1032 | 2100 | 1930 | 945 | 6860 | |

| STRA-18 | 1800 | 500 | <18 | 7.5 | 4.4 | 3910 | 3190 | 1550 | 2010 | 2130 | 1393 | 11800 | |

| STRA-20 | 2000 | 550 | <31.5 | 7.5 | 1.1 | 4270 | 3330 | 1560 | 2180 | 233 | 1337 | 16500 | |